As the new energy vehicle market in China has continued to expand, power batteries, as the "heart" of new energy vehicles, are facing a big challenge. Since 2013, China has witnessed rapid development of new energy vehicles. By 2017, the number of new energy vehicles in China has reached over 1.6 million, making China the world's largest new energy vehicle market. The Power battery, as a key component, which related technology must be adapted to the development of electric vehicle. How far the new energy vehicles can greach depends ultimately on how far the power batteries can go. Based on the technological advantages and development trends of various kinds of batteries, lithium ion batteries will be more and more widely used in hybrid electric vehicles, plug-in hybrid electric vehicles and pure electric vehicles. This kind of power battery technology is of great significance to the development of new energy automobile industry.

At present, there are over one hundred enterprises producing power batteries in China. However, due to the low degree of automation, many enterprises are characterized by low production efficiency, low qualified product rate and low efficiency of operation information interconnection. This problem makes it difficult to make substantial breakthroughs in terms of technology and consistency, which seriously affects the overall performance of power batteries and restricts the development of new energy automobile industry in China.

Based on such condition, the intelligent manufacturing of power battery came into being. In the future, the manufacturing of new energy vehicles, including power batteries, is bound to be large-scale and intelligent, featuring high precision, high speed and high reliability. Meanwhile, simulation, as an important part, will play a vital role.

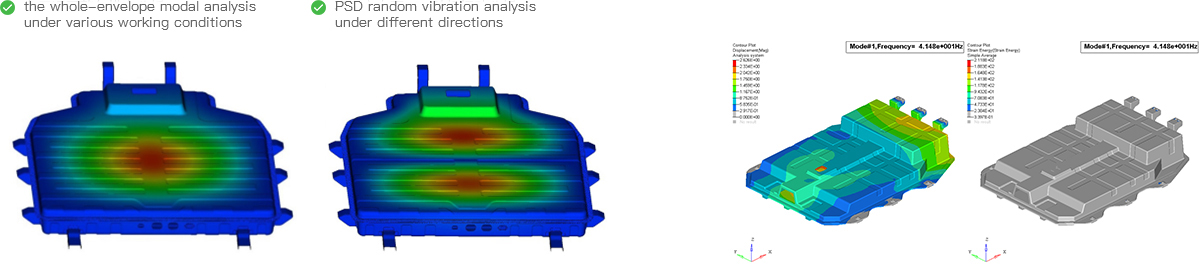

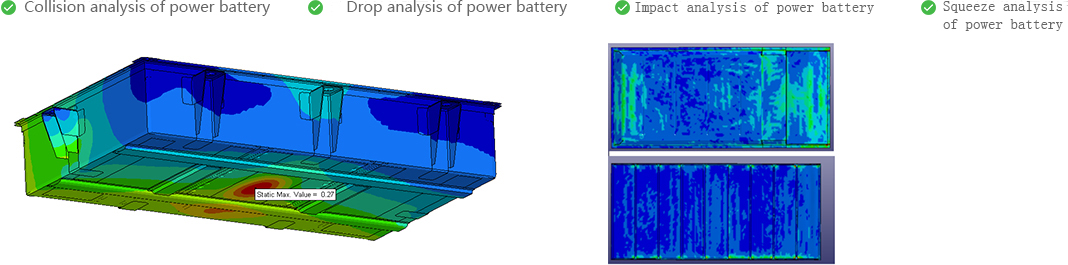

Mechanical performance analysis of new energy power battery includes: strength analysis, modal analysis, PSD random vibration analysis, collision analysis, extrusion analysis, drop analysis, impact analysis, fatigue analysis, etc.

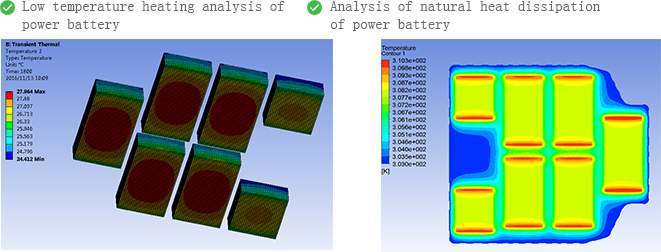

New energy power battery thermal (thermal management system) performance analysis includes: battery pack’s low-temperature charging thermal analysis, and natural cooling CFD analysis.

Electrical system simulation of new energy power battery: circuit simulation, charge-discharge process analysis, etc.

3.1 The strength and stiffness of the power battery pack

3.2 The vibration of the power battery pack

3.3 The display dynamics of the power battery

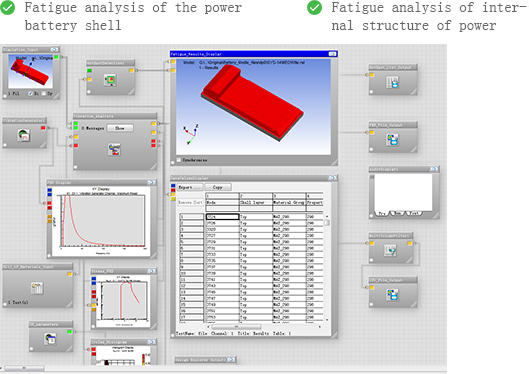

3.4 Battery fatigue

3.5 Heating and heat dissipation of the power battery

3D model import: ANSYS is specialized in the imported model, no matter the parts or the assembly. The model can be imported either through intermediate format file, or directly by the corresponding interface (interface module) into the 3D model software, which can realize real-time two-way transconductance model, and implementation model information condition, to keep the original parametric data, for the subsequent optimization design.

Modeling and model repair: ANSYS's SpaceClaim software, based on the idea of direct modeling, is more convenient to establish three-dimensional solid model or finite element model (beam element extraction, intermediate surface, internal and external fluid, spot welding, etc.), as well as model repair (chamfer removal, filling, interference surface, etc.) and other operations, and the interface is operated more easily for users.

Convenient operation interface: The analysis process of ANSYS is unified and integrated in the workbench platform. The clarity and logicality of process are strong. Various analysis types (such as structural stress analysis, modal analysis, random vibration analysis and fatigue analysis) are unified and carried out in the workbench platform, so the data conversion is very convenient.

Meshing: For mesh types, ANSYS has one dimensional mesh, two dimensional mesh (triangular/quadrilateral), and three dimensional mesh (tetrahedral/hexahedral/wedge). And the grid control methods are similar, including topology optimization, damage tolerance, expansion layer, high quality shell grid, etc. ANSYS is very skillful in grid control. Besides ANSYS meshing, ANSYS ICEM CFD, another powerful grid software, is added.

Multi-physical field coupling: The Workbench platform of ANSYS combining several items into a single form, which are structure, electromagnetic and fluid analysis, and it’s absolutely perfect operating platform for multi-physical field coupling.

Geometric modeling:ANSYS SCDM

Structural simulation analysis: ANSYS Mechanical Enterprise

Fatigue life analysis:ANSYS nCode Designlife

Fluid simulation analysis: ANSYS Meshing、ICEM CFD、ANSYS Fluent/CFX

Acceleration Module:ANSYS HPC