The actuator, or solenoid, is a device that electrically generates magnetic fields to control the armature for ideal torque and displacement. The armature is a ferromagnetic substance, which generates suction and converts electrical energy into mechanical energy when subjected to magnetic field, and is used to control the speed, direction, displacement and force of load.

Actuator, sometimes also known as brake, solenoid valve, electromagnet, etc., has a wide range of applications, such as fuel injector (solenoid valve of oil valve), power distributor (cut-out device, circuit breaker, relay, contactor, etc.), various automobile, hydraulic industrial applications, etc.

The company provides multi-level physical integrated design solutions for electromagnetism, structure, fluid and control to meet the design requirements of actuator such as electromagnetic analysis, performance optimization, temperature rise and deformation, structural stress analysis, and control system integration, so as to comprehensively solve the design problems of actuator.

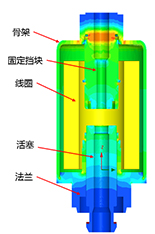

There are many structures of actuators, but the working principle is basically the same. The typical electromagnetic actuator includes a multiturn coil wound on the plate and a movable armature. In addition, the core of the casing frame provides a closed loop for flux, and figure 2 shows the geometry of the frame, magnetic pole piece, coil and armature.

When the electromagnetic actuator is connected with the voltage source, the current in the coil is passed and the magnetic flux is generated, and the armature is driven from the open position to the closed position. Some electromagnetic actuators can use a permanent magnet, assisting it in building the magnetic flux or helping the armature stay in a certain position when the coil voltage is turned off. For example, the voice coil actuator uses a permanent magnet to generate the magnetic flux and coil current interaction, thus generating lorentz force in the coil. These devices may be two-dimensional or three-dimensional structures, and the moving parts may be rotating or non-circular (such as swinging of a joystick).

The armature, plate and frame of the actuator are all ferromagnetic materials. The shape and size of the armature and the matching with the magnetic plate will affect the force index of the actuator at the closing time. In addition, the coil design determines its resistance and inductance, especially inductance, as it is proportional to the square of coil turns times the total reluctance of the nonlinear ferromagnetic material and air gap. The ratio of L/R is the normal electrical time of the device, which determines the speed of current rise in the coil, while the speed of magnetic field establishment in the device depends on the electric eddy current, so the electromagnetic diffusion time also affects the performance of the actuator.

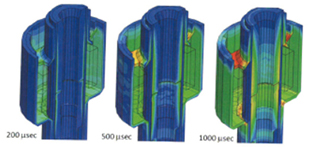

During the rapid rise of the coil current, the magnetic flux diffuses to the entire magnetic circuit of the actuator, and is concentrated on the inner surface of the actuator. This will delay the setting up time of the electromagnetic force of the armature, thus delaying the closing time. Similarly, when the applied voltage source is switched off and the magnetic field is withdrawn from the device, the reopening time of the actuator armature will be delayed due to the presence of residual magnetism. As time goes on, the magnetic field passes through the thick wall of the equipment, and the stress on the armature increases. Therefore, the magnetic pole shape, material and coil design will directly affect the magnetic diffusion process, and further affect the closing time of actuator. Maxwell transient field solver can analyze the diffusion process of local magnetic field after the eddy current.

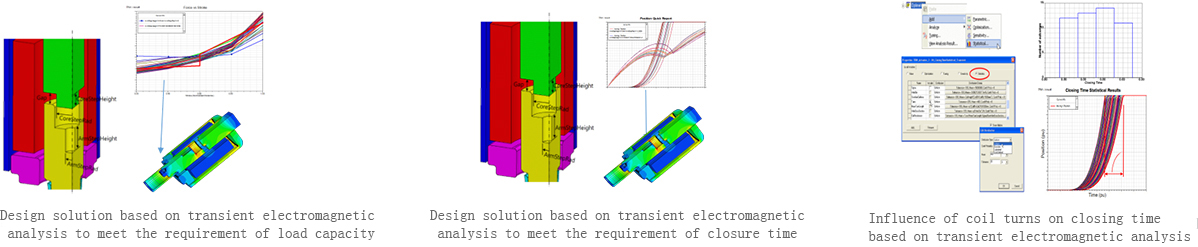

Maxwell's static or transient solvers enable two-dimensional and three-dimensional electromagnetic field analysis of actuators. Generally, parameters such as coil shape, turns, line diameter and geometric size are set as parameterized/optimized variables in static simulation, and a set of curves reflecting force and position is output by changing coil current and armature position. Since Maxwell began to used automatic adaptive mesh generation, it is very easy to parameterize/optimize the scan of variables.

In addition to the static method, Maxwell transient solver can be used to simulate the speed problem of the armature when reaching the closed position, considering the electrical control and mechanical load conditions. For example, the external excitation voltage source is an arbitrary waveform (or using the circuit editor tool provided by Maxwell), while the non-linearity of materials, the motion equation of machinery (including damping, load bearing, and all of them can be a function of position, velocity, or time), and the eddy current and magnetic diffusion are considered.

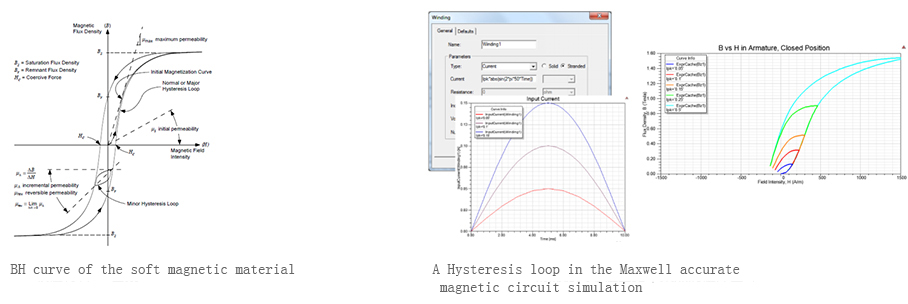

Most actuators adopt soft magnetic materials as magnetic path.Because the BH loop of soft magnetic material is narrow and the coercivity is small, the initial magnetization curve is usually used to calculate the BH operating point. However, when the coil of the actuator is cut off, the magnetic field will not fall to 0 and there will be residual magnetism, which will directly affect the electromagnetism and closing time calculation of the actuator. Maxwell can truly consider the characteristics of soft magnetic materials of actuators through the modeling function of vector hysteresis materials, and accurately analyze the residual magnetism effect of soft armor materials, so as to accurately calculate the transient electromagnetic characteristics of actuators such as magnetic field diffusion, electromagnetic force and closure time.

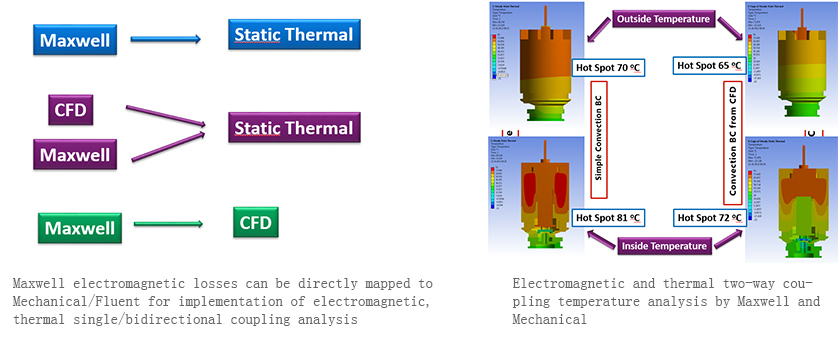

The coil and core losses obtained by Maxwell's transient electromagnetic field simulation analysis can be mapped to Mechanical or CFD (computational fluid dynamics) software, Fluent, for thermal analysis by ANSYS WB environment, as shown in figure 8. Its coupling mode including: Electromagnetic field analysis for the total loss of spatial distribution of thermal model is mapped to a Fluent, through accurate considering complex thermal environment, including convection and heat transfer, direct calculation of temperature rise and the temperature of components of data back to the temperature of the modified material in Maxwell's attribute and to recalculate the loss, so two-way coupling iterative, get actuator coil and iron core components such as steady-state temperature;In Mechanical temperature field calculation using simple Settings, namely direct definition of coefficient of heat transfer, or the heat transfer coefficient calculated by the Fluent software, and then through the electromagnetic - thermal transient thermal performance and thermal cycle analysis after the iteration times get steady temperature of the actuator, the process of the simulation calculation speed than the direct calculation of temperature rise fast in the Fluent software, and the simulation precision is greatly improved.

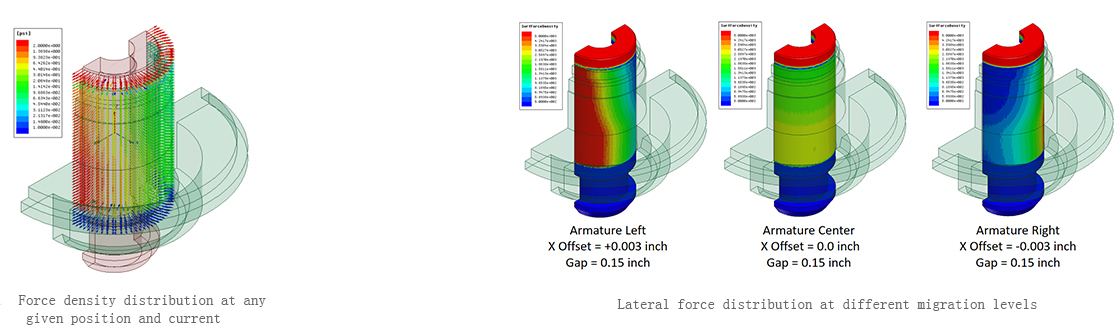

The eccentricity of actuator during assembly will affect the performance of actuator. If the armature moves off the center, it will lead to lateral electromagnetic force and cause excessive friction on the bearing surface. At the same time, eccentricity may be overall eccentricity, or axial eccentricity, or axial tilt. ANSYS Maxwell can display the force density distribution at any position and current density by means of cloud or vector diagram.

The structural strength of actuator and the performance of its natural frequency system also have a great impact when the actuator starts working condition and working condition of the maximum travel. ANSYS Workbench can also accurately analyze the structural strength and natural frequency of actuator under different working condition.

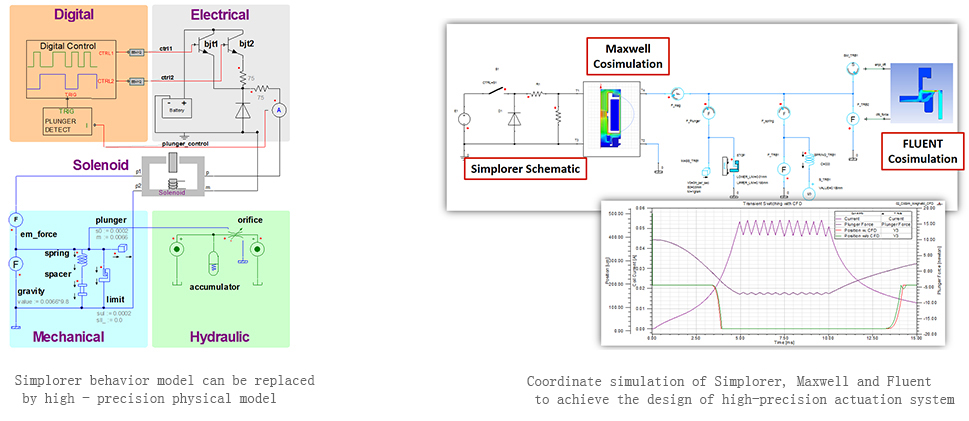

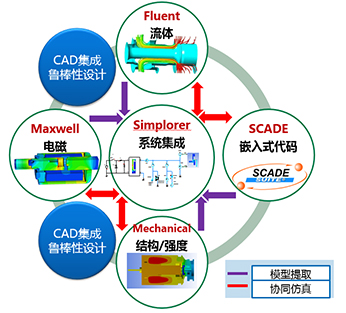

The actuator design should take not only its electromagnetic and multi-physical domain coupling characteristics, but also its power supply and control circuit integration into considerations. Simplorer can realize the design of behavior-level actuating system and quickly analyze its performance. The design of high-precision physical prototype-level actuation system can also be realized by cooperating with Maxwell simulation (taking into account the nonlinear effect of materials, eddy current and magnetic diffusion, etc.), or through the interface of the reduced price model (considering only the position of actuator and current parameterized scanning relation, and ignoring the eddy current effect of coil), so as to accurately analyze its performance. The multilevel modeling function of Simplorer platform is shown in figure 9, and the high-precision actuation system design model of Simplorer platform is shown in figure 10, including equipment-level power electronics devices, closed-loop control systems, accurate two-dimensional or three-dimensional actuator models, and mechanical or hydraulic loads. The driving circuit and Maxwell finite element model transient link are used for collaborative simulation. The mechanical pin is directly connected to a device defining weight, force, spring and stop limit.

The design solution of ANSYS actuator not only provides finite element analysis and optimization design tools for electromagnetic field, but also can realize static and transient magnetic field analysis and performance optimization of actuator. It also provides static thermal and transient fluid thermal analysis tools, which can realize electromagnetic and thermal bidirectional coupling analysis. And it also provides the circuit and system design tools, so as to achieve higher level from behavior to physical prototype, to get the multi-level and high precision system design, which can help users efficiently realize the seamless multi-physical domain integration design process of actuator. Because of high precision simulation, we could minimize production prototype, shorten the development cycle, and lower development costs, which is conducive to the user among the fierce competitors.